STEEL FIBERS FOR TUNNEL SHOTCRETE

Value engineering solution to traditional reinforcement applications in order to increase the post-cracking flexural strength of shotcrete allowing it to carry flexural loads after cracking.

PURPOSE OF STEEL FIBERS IN TUNNEL SHOTCRETE

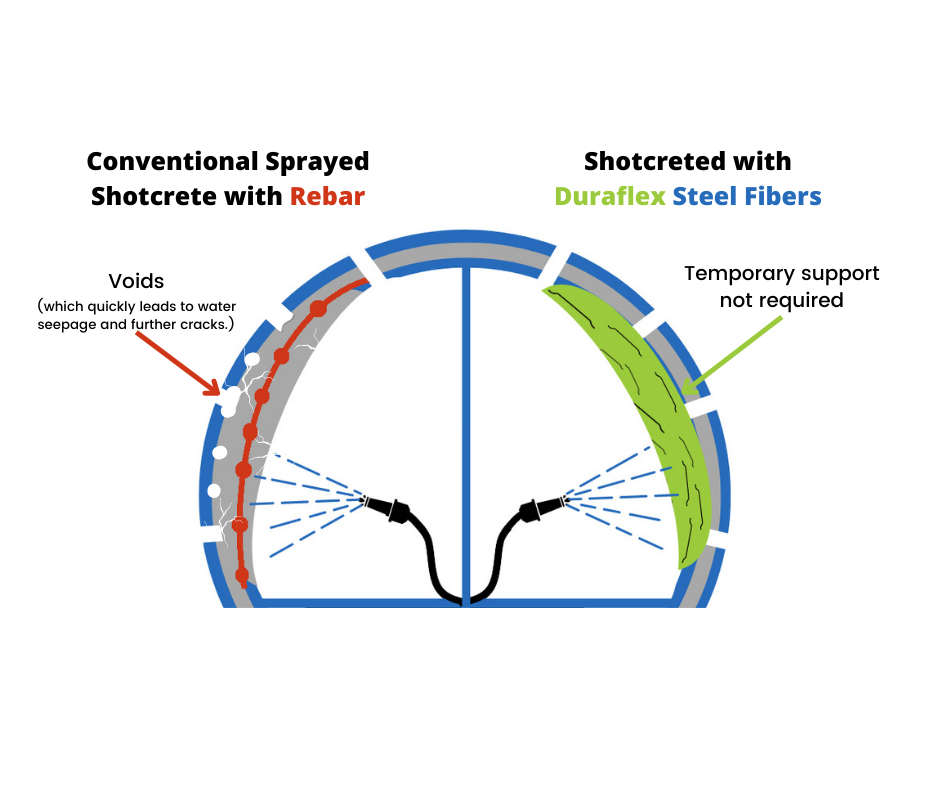

Shotcrete is a construction process in which concrete is projected at a high velocity on a surface which can be either vertical, complex shapes or overhead surfaces. This process ensures the reinforcement blends with concrete and is placed in a manner to provide adhesion to the substrate in each and every corner of the portion. Also, traditional reinforcement like Rebar provides tensile strength in a specified direction following the tunnel lining whereas steel fiber provides 3 Dimensional physical property enhancement. Due to the 3D effect of steel fiber reinforcement, there is less overbreak for the lining which helps in attaining a uniform layer of rock contour.

Shotcreting is a blend of reinforcement and concrete as an absolute package having the advantage of lining the tunnel in a speedy constructional process. Another advantage of this process is providing early bearing capacity which provides support to the poor rock condition which is activated by driving the cross-section of the tunnel. Orientation of shotcrete lining has to be designed based on the geological conditions of the rock which significantly plays a major role in determining the bearing characteristics of the tunnel lining.

Customising the fiber type, dosage, aspect ratio and the concrete mix offers a shotcrete lining that enhances energy absorption capacity, ductility and resistance to fatigue of the concrete.

HOW STEEL FIBERS HELP IN TUNNEL SHOTCRETE

- Enhances Ductility under given Tension and Pressure

- Improved Impact strength

- Resistant to Fatigue behavior

- Less Susceptibility for Spalling

- Enhances Durability

- Lowers Crack widths in Operational state

- Improved capacity for Bending tensile in all 3 spatial directions

- Increased factor of Safety at Crack stage better than Rebar

Application of Steel Fiber in Shotcrete

- Slope Stabilization

- Repair and Strengthening

- Tunnelling

- Mining

OUR PRODUCTS

APPLICABLE PRODUCTS

Our team of dedicated professionals has the abundant experience to ensure that the services offered to the clients are best-in-class and promptly executed.

Duraflex Glued/Loose Hooked End 45/35

Duraflex Glued/Loose Hooked End 50/30