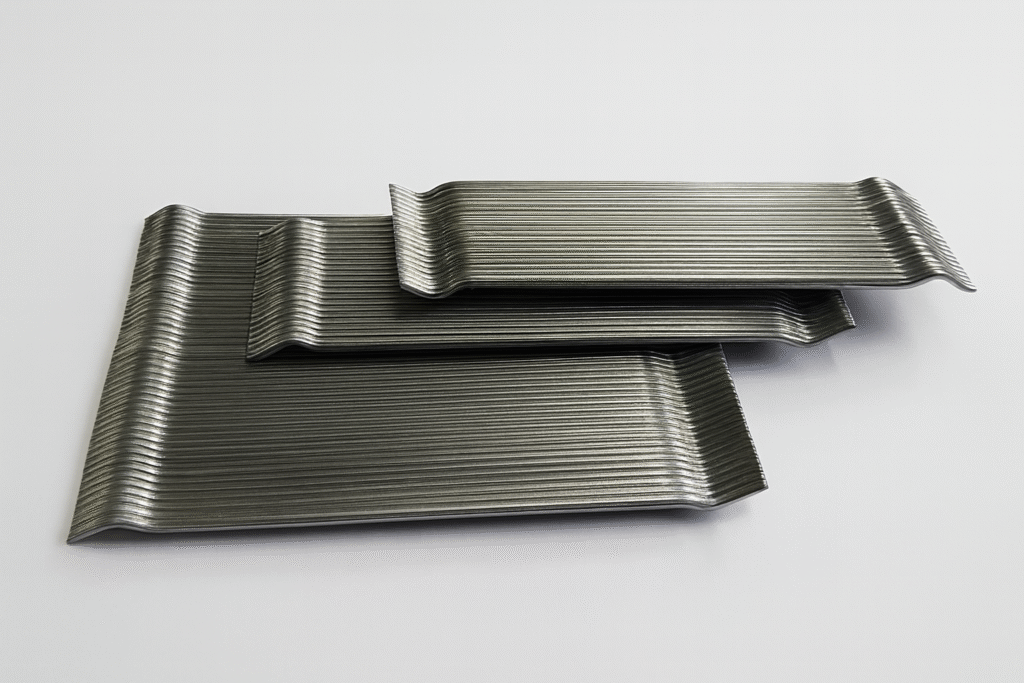

Duraflex™ – Delta Loop End Steel Fiber ( Patent Applied )

Duraflex™ Delta Loop End Steel Fibers are engineered to deliver enhanced strength, durability, and multi-directional reinforcement in concrete. Made from low-carbon drawn wire and featuring a ultra high tensile strength exceeding 1850 MPa, these fibers significantly improve the structural integrity of industrial floors, pavements, and heavy-duty concrete applications.

Their loop-end anchorage ensures strong bonding with the concrete matrix and tensile strength for enhanced concrete performance, while the fiber design minimizes balling issues and improves construction efficiency.

Key performance of Duraflextm Delta Loop End Steel Fibers, include a tensile strength exceeding 1850 – 2300 MPa, ductility of at least > 1.4%, and the ability to achieve a residual flexural strength (Fr₃k) greater than 4 MPa in concrete at dosages of less than 0.5% by volume, in accordance with the EN 14651 standard.

Purpose Of Duraflex™ – Delta Loop End Steel Fiber

Designed to enhance concrete performance by improving load capacity, reducing cracks, and ensuring long-term durability.

- Increase Structural Strength: Enhances load-bearing performance of concrete elements.

- Control Shrinkage Cracks: Effectively reduces early-age and drying shrinkage cracks.

- Improve Durability: Ensures longer-lasting concrete under industrial and heavy-load conditions.

- Enhance Multi-Directional Reinforcement: Provides superior 3D reinforcement throughout the slab.

- Boost Construction Efficiency: Reduces labor, installation time, and steel reinforcement needs.

- Reliable Compatibility: Conforms to EN 14889-1 and ASTM A820 M04 standards.

Applications Of Duraflex™ – Delta Loop End Steel Fiber

- Industrial & Warehouse Flooring Increased strength and toughness for high-load environments.

- Roads & Pavements Improved durability and resistance to cracking.

- Heavy-Duty Slabs Strong load transfer and reduced reinforcement requirements.

- Precast Concrete Elements Enhanced tensile capacity and long-term stability.

- Tunnel shotcreting tunnel lining segments, hydro-electric power tunnels, high-speed railway sleepers, pavements, and rock support.

OUR PRODUCTS

APPLICABLE PRODUCTS

Our team of dedicated professionals has the abundant experience to ensure that the services offered to the clients are best-in-class and promptly executed.

Delta Loop End 60-35